The Future of Quality Control: Automated Inspection Systems in Manufacturing

- jeksonvision128

- Oct 4, 2024

- 4 min read

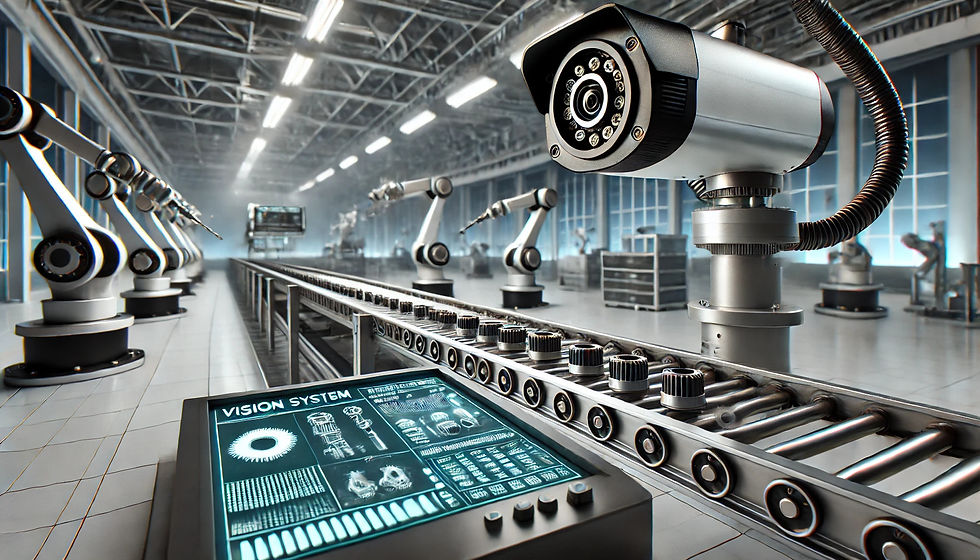

As the manufacturing industry evolves, the demand for high-quality products and efficient production processes has never been greater. To meet these challenges, manufacturers are increasingly turning to Automated Inspection Systems—advanced technologies that provide precise, real-time quality control throughout the production process. By leveraging automation, artificial intelligence (AI), and machine vision, these systems revolutionize quality control, ensuring that products meet stringent standards while reducing human error, improving efficiency, and driving cost savings.

What Are Automated Inspection Systems?

An Automated Inspection System is a technology that uses sensors, cameras, AI algorithms, and sometimes robotic systems to inspect products as they move along the production line. These systems are designed to detect defects, deviations, or inconsistencies in products without requiring human intervention. Automated inspection is capable of identifying imperfections such as cracks, scratches, misalignments, or dimensional errors with remarkable accuracy, and they do so at a much faster rate than manual inspections.

The introduction of these systems into manufacturing processes ensures that quality control is not only faster but also more consistent and reliable, helping manufacturers deliver higher-quality products to market.

Key Components of an Automated Inspection System

Machine Vision Technology: Machine vision is one of the core components of an Automated Inspection System. It uses high-resolution cameras and sensors to capture images or videos of products as they pass through the inspection line. These images are then analyzed to identify defects or variations from set standards.

Artificial Intelligence and Machine Learning: AI and machine learning algorithms process the data collected by machine vision systems. These algorithms are trained to recognize patterns, compare them against established quality criteria, and detect any deviations or flaws. Over time, machine learning models improve their accuracy, making the inspection process even more precise.

Robotics: In some advanced Automated Inspection Systems, robots are used to manipulate objects during the inspection process. This allows for more thorough inspections of products from multiple angles, enhancing the system’s ability to detect hidden defects.

Data Analytics: Automated Inspection Systems generate vast amounts of data related to product quality. Advanced analytics tools help manufacturers track trends, understand defect patterns, and make data-driven decisions to improve production processes and product designs.

Benefits of Automated Inspection Systems in Manufacturing

Improved Accuracy and Consistency: One of the main advantages of Automated Inspection Systems is their ability to consistently detect even the smallest defects, reducing the risk of faulty products reaching consumers. Human inspections can vary due to fatigue, bias, or oversight, whereas automated systems maintain a high level of accuracy throughout the entire production cycle.

Increased Production Speed: Automated inspection happens in real-time, without slowing down the production line. Unlike manual inspection, which can be time-consuming and prone to errors, automated systems can inspect products at high speed, ensuring that manufacturers meet production targets without compromising on quality.

Cost Savings: By reducing the reliance on manual labor for quality control and catching defects early in the production process, Automated Inspection Systems help manufacturers cut costs. Early defect detection reduces waste, rework, and recalls, while the labor saved by automating inspections can be redirected to more value-added tasks.

Enhanced Product Quality: Automated systems ensure that only products meeting the highest standards leave the production line. By detecting and removing defective products, manufacturers can ensure that their final output meets customer expectations, leading to improved brand reputation and customer satisfaction.

Scalability and Flexibility: Automated Inspection Systems can easily be adapted to different production environments and product types. Whether used in automotive, electronics, pharmaceuticals, or food and beverage industries, these systems can be customized to meet specific quality control requirements and scale as production volumes increase.

Applications of Automated Inspection Systems Across Industries

Automotive Industry: In automotive manufacturing, precision and safety are critical. Automated Inspection Systems are used to inspect components such as engine parts, body panels, and tires for defects that could compromise vehicle safety. These systems ensure that every component meets the strict safety and performance standards required in the automotive sector.

Electronics and Semiconductors: The electronics industry requires microscopic precision, making it ideal for automated inspections. These systems can detect defects in circuit boards, chips, and electronic components at a granular level, ensuring high-quality products that meet technical specifications.

Pharmaceuticals: In the pharmaceutical industry, quality control is vital to ensuring product safety and efficacy. Automated Inspection Systems are used to inspect pills, capsules, and vials for defects such as cracks, chips, or contamination. These systems also ensure accurate packaging and labeling, reducing the risk of product recalls.

Food and Beverage Industry: Automated inspection in food and beverage manufacturing helps ensure product consistency and safety. Systems can detect packaging defects, foreign objects, or irregularities in food products, helping manufacturers comply with food safety regulations and maintain consumer trust.

Future Trends in Automated Inspection Systems

The future of Automated Inspection Systems is promising, with several key trends expected to shape the industry:

AI and Deep Learning: As AI algorithms become more sophisticated, Automated Inspection Systems will become even more capable of detecting complex defects. Deep learning models will allow systems to learn from past inspections, continuously improving their accuracy and efficiency.

Edge Computing: With edge computing, data processing can occur closer to the source, reducing latency and enabling faster real-time decisions. This will make Automated Inspection Systems more responsive, especially in high-speed production environments.

3D Vision Systems: Traditional 2D vision systems are evolving into 3D systems, which can provide a more comprehensive analysis of products, enabling better detection of surface and structural defects.

Integration with Digital Twins: Digital twin technology, which creates a virtual model of a product or production process, will allow manufacturers to simulate inspections and optimize their processes before physical production begins.

Conclusion

The future of quality control in manufacturing lies in Automated Inspection Systems. These advanced technologies are revolutionizing the way manufacturers maintain quality, combining the power of machine vision, AI, and data analytics to deliver unprecedented levels of accuracy and efficiency. By adopting Automated Inspection Systems, manufacturers can not only ensure that their products meet the highest standards but also improve production speed, reduce costs, and enhance overall operational efficiency.

As automation continues to advance, manufacturers that embrace these systems will be well-positioned to stay ahead in an increasingly competitive global market.

Comments