Revolutionizing Manufacturing with Vision System Camera Inspection

- jeksonvision128

- Jan 8, 2025

- 3 min read

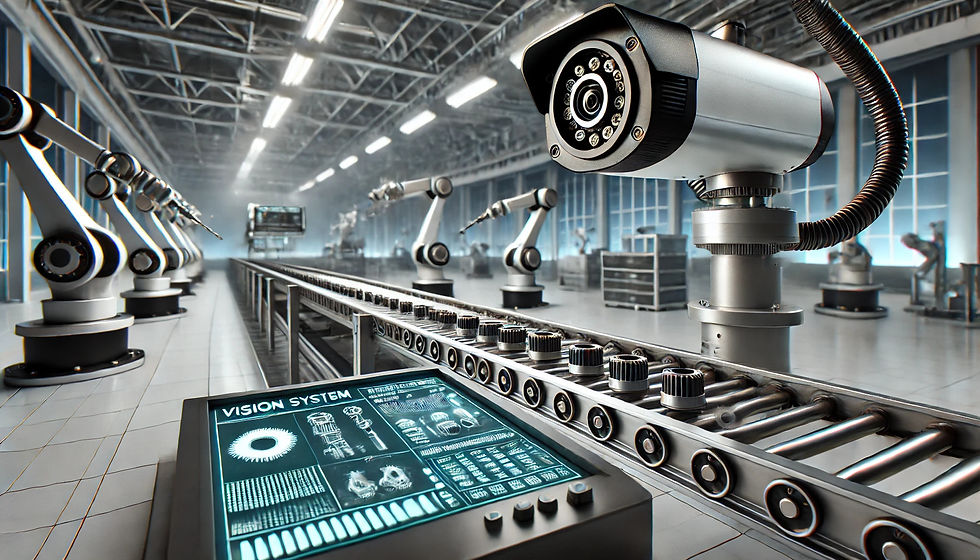

In the ever-evolving world of manufacturing, quality and efficiency are critical to staying competitive. One of the most transformative innovations in recent years is the use of Vision System Camera Inspection. This cutting-edge technology is reshaping how manufacturers ensure product quality, streamline processes, and maintain compliance with industry standards.

What is Vision System Camera Inspection?

Vision System Camera Inspection refers to the use of advanced imaging systems to inspect, analyze, and validate products on a production line. These systems use high-resolution cameras, lighting, and specialized software to detect defects, measure dimensions, and ensure that products meet strict quality requirements.

Unlike manual inspection methods, vision systems operate at incredible speeds and offer unparalleled accuracy, making them indispensable in modern manufacturing environments.

Key Benefits of Vision System Camera Inspection

Improved Quality Control: Vision system cameras detect defects with precision, identifying imperfections that might be invisible to the human eye. This ensures that only high-quality products reach the market, enhancing customer satisfaction and reducing returns or recalls.

Increased Efficiency: By automating the inspection process, manufacturers can significantly speed up production lines. These systems can process thousands of items per hour, reducing bottlenecks and maximizing throughput.

Cost Reduction: Early detection of defects minimizes waste and rework, saving both time and resources. Additionally, the reduced need for manual inspection lowers labor costs and increases overall profitability.

Compliance and Traceability: Many industries, such as pharmaceuticals and food processing, have strict regulatory requirements. Vision systems ensure that products comply with these standards, and their ability to store detailed inspection data supports traceability in the event of an audit.

How Vision System Camera Inspection Works

Image Acquisition: High-resolution cameras capture images of products as they pass through the production line. Advanced lighting techniques ensure consistent and clear images for accurate analysis.

Image Processing: Sophisticated algorithms analyze the captured images in real-time, identifying defects such as scratches, misalignments, or missing components.

Decision Making: The system compares the analyzed data to predefined standards. If a product does not meet these criteria, it is flagged for rejection or further inspection.

Integration with Automation: Vision systems can be integrated with robotic arms or other automation tools, enabling seamless removal of defective products or adjustments to the production process.

Applications of Vision System Camera Inspection

Vision System Camera Inspection is versatile and widely used across various industries, including:

Automotive: Inspecting components for defects, ensuring proper assembly, and verifying part dimensions.

Pharmaceuticals: Verifying correct labeling, inspecting blister packs, and ensuring that medicine bottles are properly filled and sealed.

Food and Beverage: Checking packaging integrity, verifying expiration dates, and ensuring correct product labeling.

Electronics: Inspecting circuit boards, detecting soldering defects, and verifying component placements.

Future Trends in Vision System Camera Inspection

AI and Machine Learning Integration: Future systems will incorporate artificial intelligence to learn from previous inspections, improving accuracy and reducing false positives over time.

3D Vision Technology: Moving beyond 2D imaging, 3D vision systems can provide depth information, enabling more precise measurements and defect detection.

Cloud Connectivity and IoT: Vision systems connected to the cloud will enable real-time monitoring and analysis across multiple production facilities, enhancing scalability and efficiency.

Edge Computing for Faster Processing: Edge computing will allow vision systems to process data locally, reducing latency and enabling faster decision-making.

Challenges and Considerations

While Vision System Camera Inspection offers numerous benefits, manufacturers must address certain challenges, including:

Initial Investment Costs: High-quality systems require a significant upfront investment.

Customization Needs: Tailoring systems to specific production lines can be complex.

Maintenance and Upgrades: Regular calibration and software updates are essential for optimal performance.

Conclusion

Vision System Camera Inspection is revolutionizing the manufacturing landscape, delivering unparalleled quality, efficiency, and cost savings. As technology continues to evolve, these systems will become even more integral to production processes, ensuring that manufacturers stay ahead in an increasingly competitive market.

By embracing this innovation, industries can achieve higher standards, foster consumer trust, and pave the way for a future of smarter, more efficient manufacturing.

Comments