Ensuring Quality Control with Advanced Capsules Inspection Systems

- jeksonvision128

- Dec 19, 2024

- 3 min read

In the pharmaceutical industry, maintaining stringent quality control is paramount, especially when dealing with products like capsules. Capsules are widely used for drug delivery due to their ability to encapsulate active ingredients effectively. However, ensuring the safety, efficacy, and consistency of these capsules requires robust inspection systems to identify defects, ensure uniformity, and maintain regulatory compliance. Advanced capsules inspection systems have become an essential tool in this process, allowing manufacturers to uphold the highest standards of product quality.

The Importance of Capsules Inspection

Capsules, whether filled with powders, liquids, or gels, must meet strict quality standards. The integrity of a capsule—its size, shape, weight, fill volume, and seal—is critical to ensuring that the product is both safe and effective for consumption. Defects such as cracks, broken shells, variations in fill weight, and seal integrity can compromise the capsule’s performance, leading to inconsistent dosing, reduced bioavailability, and potential health risks to consumers. Thus, meticulous inspection during the production process is essential.

Challenges in Capsules Inspection

Traditional methods of inspecting capsules involve manual checks, which are labor-intensive, time-consuming, and prone to human error. These methods may miss defects, particularly for high-speed production lines, where manual inspection becomes increasingly difficult. Additionally, the complexity of modern capsule designs and the variety of materials used in their construction pose further challenges to quality control. With the growing emphasis on regulatory compliance and stringent guidelines from bodies such as the FDA and EMA, the need for advanced inspection technologies is more critical than ever.

Advanced Capsules Inspection Systems

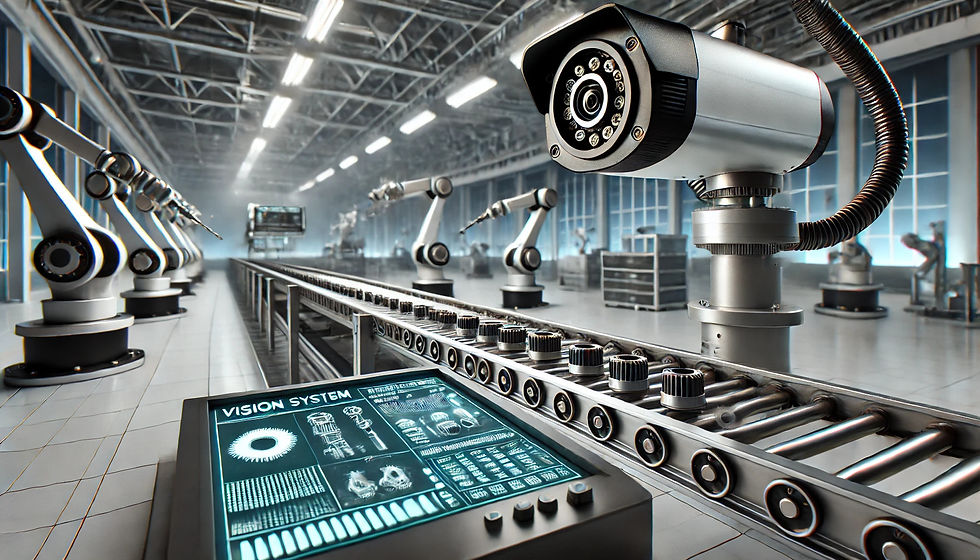

Modern capsules inspection systems leverage cutting-edge technology to ensure each capsule meets the required specifications. These systems employ a combination of advanced imaging technologies, artificial intelligence (AI), and machine learning algorithms to automate the inspection process. Here are some key features of these systems:

High-Speed Imaging: High-resolution cameras are used to capture detailed images of capsules at various stages of production. This allows for the detection of even the smallest defects—cracks, dents, and inconsistencies in the shell.

Machine Vision Systems: These systems use sophisticated software to analyze images in real-time. By comparing captured images with reference models, they can identify and classify defects quickly and accurately. This automation reduces the likelihood of human error and increases inspection speed, enabling manufacturers to monitor thousands of capsules per minute.

AI and Machine Learning: AI-driven systems go beyond simple defect detection. They can predict potential issues by learning from vast datasets, providing insights into capsule quality trends and potential areas for improvement. This predictive capability is especially useful for preemptively addressing issues such as fill volume discrepancies or shell thickness variations.

Laser Inspection Systems: Laser technology is used to measure the thickness and uniformity of capsule shells. This method is non-destructive and provides precise data, allowing for early detection of defects that might not be visible through visual inspection alone.

X-Ray Inspection: X-ray systems are used to detect foreign objects inside capsules, such as metal fragments or glass particles, that could pose serious health risks. These systems are particularly useful for inspecting capsules filled with sensitive materials that require protection from external contamination.

Benefits of Advanced Inspection Systems

The adoption of advanced capsules inspection systems offers numerous benefits:

Enhanced Quality Control: By automating the inspection process, these systems significantly reduce the risk of defects, ensuring a consistent product quality.

Increased Production Efficiency: High-speed inspection systems allow manufacturers to keep up with high-volume production lines without compromising on quality.

Regulatory Compliance: Advanced systems provide accurate documentation and reporting capabilities, helping manufacturers meet regulatory requirements and audits.

Cost Savings: By reducing waste and minimizing recalls due to defective products, manufacturers can cut costs associated with rework and customer complaints.

Conclusion

Ensuring the quality of capsules through advanced inspection systems is crucial in the pharmaceutical industry. These systems not only enhance the safety and efficacy of capsules but also streamline production processes, increase efficiency, and maintain regulatory compliance. As technology continues to evolve, the integration of AI, machine learning, and advanced imaging techniques will play a vital role in the future of capsules inspection, providing even greater accuracy and reliability in quality control. By investing in these advanced systems, pharmaceutical manufacturers can meet the growing demand for high-quality, safe, and effective capsule-based drug delivery systems.

Comments