Enhancing Traceability with Advanced 2D Code Printing for Pharma

- jeksonvision128

- Dec 19, 2024

- 3 min read

In the pharmaceutical industry, traceability and transparency are critical to ensuring patient safety, regulatory compliance, and supply chain efficiency. 2D Code Printing for Pharma has emerged as a transformative solution to meet these needs. With its ability to encode detailed information in compact formats, 2D code printing has revolutionized how pharmaceutical products are identified, tracked, and authenticated throughout their lifecycle.

This article explores the importance of 2D code printing in the pharmaceutical sector, its applications, benefits, and role in advancing traceability and quality assurance.

What is 2D Code Printing?

2D code printing involves creating two-dimensional barcodes, such as QR codes or Data Matrix codes, that can store significantly more information than traditional linear barcodes. These codes can encode data such as:

Product batch numbers

Expiry dates

Manufacturing details

Unique serial numbers

Regulatory compliance data

Unlike traditional barcodes, 2D codes are compact and can be scanned from any angle, making them ideal for small pharmaceutical packaging like blister packs, ampoules, and vial labels.

The Importance of 2D Code Printing for Pharma

Regulatory Compliance:

Many regulatory bodies, including the U.S. FDA and the European Medicines Agency, mandate serialization and traceability for pharmaceutical products. 2D codes ensure compliance by encoding essential product data.

Counterfeit Prevention:

Counterfeit drugs are a major global concern, endangering patient safety and tarnishing brand reputations. 2D codes allow for easy verification of product authenticity at any point in the supply chain.

Efficient Supply Chain Management:

With 2D codes, manufacturers, distributors, and retailers can track products in real time, improving inventory management and reducing errors.

Recall Management:

In case of product recalls, 2D code printing enables precise identification of affected batches, minimizing the scope and impact of recalls.

Applications of 2D Code Printing in Pharma

Unit-Level Serialization:

Each unit of a pharmaceutical product is assigned a unique identifier, enabling granular tracking and tracing.

Packaging Labeling:

2D codes are printed on labels for blister packs, bottles, and cartons, providing essential product information in a compact format.

Cold Chain Monitoring:

Integrating temperature and condition data into 2D codes ensures that cold chain products, such as vaccines, remain within specified conditions during transportation.

Point-of-Sale Authentication:

Pharmacies and healthcare providers can scan 2D codes to verify the authenticity of medications before dispensing them to patients.

Benefits of 2D Code Printing for Pharma

Enhanced Traceability:

Enables real-time tracking of products from manufacturing to the end user.

Improved Patient Safety:

Reduces the risk of counterfeit drugs entering the market and ensures that patients receive authentic, high-quality medications.

Compact Data Encoding:

Stores comprehensive information in a small space, ideal for compact pharmaceutical packaging.

Streamlined Logistics:

Simplifies inventory management and reduces errors in order fulfillment.

Global Standardization:

Adheres to GS1 standards, ensuring compatibility with global supply chain systems.

How 2D Code Printing Works

Data Encoding:

Product information, such as serial numbers and batch details, is encoded into a 2D code format like Data Matrix or QR code.

Printing Technology:

Advanced printing technologies, such as laser marking or inkjet printing, ensure high-resolution codes that are easily scannable.

Integration with Systems:

The printing process is integrated with enterprise systems for seamless serialization and data management.

Verification:

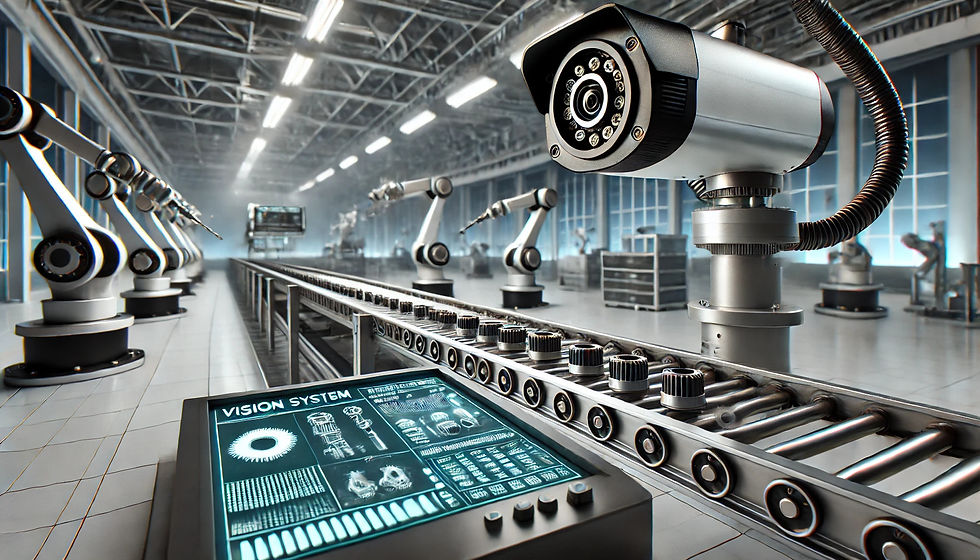

Vision inspection systems validate the accuracy and readability of printed codes, ensuring compliance and reliability.

Future Trends in 2D Code Printing for Pharma

As technology continues to evolve, 2D code printing is expected to integrate more advanced features:

Smart Packaging:

Interactive 2D codes linked to digital platforms will provide patients and healthcare providers with instant access to product information, usage instructions, and safety guidelines.

Blockchain Integration:

2D codes combined with blockchain technology will enable tamper-proof traceability, enhancing security and transparency.

Sustainability:

Innovations in eco-friendly printing materials and methods will align 2D code printing with sustainability goals in pharmaceutical manufacturing.

Enhanced Data Storage:

Future 2D codes may store larger datasets, enabling even more detailed tracking and reporting capabilities.

Conclusion

2D Code Printing for Pharma is more than a tool for labeling; it is a cornerstone of modern pharmaceutical manufacturing, ensuring traceability, authenticity, and compliance. By enabling real-time tracking and detailed product information, it enhances patient safety and supports the global fight against counterfeit drugs.

As the pharmaceutical industry embraces digital transformation, 2D code printing will continue to play a pivotal role in advancing supply chain efficiency and quality assurance, ultimately fostering a safer and more transparent healthcare ecosystem.

Comments