Spotting Imperfections: The Art and Science of Pin Hole Detection

- jeksonvision128

- Jan 12, 2024

- 3 min read

In the intricate world of manufacturing, where precision is paramount, the art and science of pin hole detection play a crucial role in ensuring product quality. Pin holes, often imperceptible to the naked eye, can have far-reaching consequences in various industries. This blog delves into the intricacies of pin hole detection, exploring how the convergence of art and science in this process contributes to flawless products, manufacturing excellence, and customer satisfaction.

The Unseen Culprits: Understanding Pin Holes

Microscopic Intruders

Pin holes, tiny breaches in materials, are often microscopic in nature, making them elusive and challenging to identify through conventional means. Despite their small size, these imperfections can compromise the integrity of a wide range of products, from packaging materials to electronic components.

Diverse Industry Impacts

Pin holes can have diverse impacts across industries. In the food and beverage sector, they may affect the freshness and shelf life of products, while in electronic manufacturing, they can lead to component failure. Understanding the potential consequences emphasizes the critical need for effective pin hole detection.

The Art of Visual Inspection

Trained Eyes and Attention to Detail

Visual inspection remains an integral part of the art of pin hole detection. Skilled technicians equipped with an acute attention to detail are essential for identifying potential imperfections. Their trained eyes become adept at recognizing subtle variations in materials that may indicate the presence of pin holes.

Enhancing Visual Inspection Techniques

Advancements in technology enhance the art of visual inspection. Microscopes, magnifying tools, and high-resolution cameras provide inspectors with the means to scrutinize materials at a microscopic level, uncovering pin holes that might escape traditional visual examination.

The Science Behind Pin Hole Detection

Non-Destructive Testing Methods

Science contributes significantly to pin hole detection through non-destructive testing methods. Techniques such as ultrasonic testing, eddy current testing, and pressure decay testing allow for the identification of pin holes without compromising the structural integrity of the material.

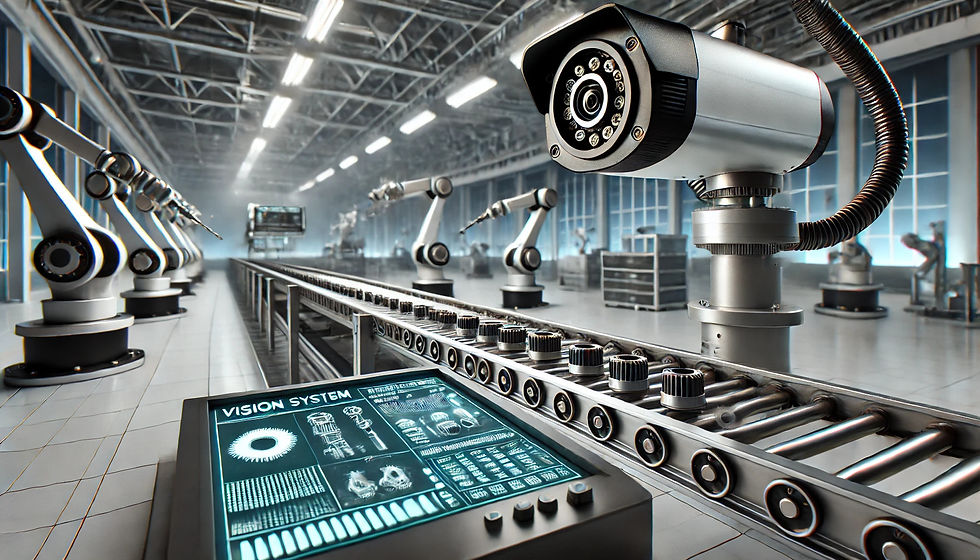

Automated Inspection Systems

The marriage of science and automation is evident in modern pin hole detection systems. Automated inspection systems utilize advanced sensors and imaging technologies to swiftly scan materials for imperfections. These systems not only enhance accuracy but also increase the speed and efficiency of the detection process.

Industry-Specific Applications

Packaging Industry

In the packaging industry, pin hole detection is vital to ensure the integrity of materials used for containing food, beverages, pharmaceuticals, and other products. Pin holes could compromise the freshness and safety of these items, making detection a critical quality control measure.

Electronics Manufacturing

Pin hole detection is equally crucial in electronics manufacturing, where tiny imperfections could lead to electrical failures. Advanced testing methods and automated inspection systems are paramount in ensuring the reliability and functionality of electronic components.

Continuous Improvement and Customer Satisfaction

Quality Assurance

The art and science of pin hole detection contribute to quality assurance in manufacturing processes. Detecting and addressing pin holes early in the production cycle prevent defective products from reaching the hands of consumers, ensuring a higher standard of quality.

Customer Satisfaction

Flawless products resulting from effective pin hole detection translate into increased customer satisfaction. Whether it's a perfectly sealed food package or a reliable electronic component, customers benefit from products that meet and exceed quality expectations.

Conclusion: Mastering the Balance

Mastering the art and science of pin hole detection is about striking a balance between human expertise and technological innovation. Visual inspection remains an essential skill, complemented and enhanced by cutting-edge detection methods. As industries continue to evolve, the commitment to spotting imperfections ensures that products meet the highest standards of quality, ultimately benefiting manufacturers and delighting customers with impeccable, reliable goods.

Comments