Seeing Beyond: The Role of Vision Cameras in Industrial Automation

- jeksonvision128

- May 14, 2024

- 2 min read

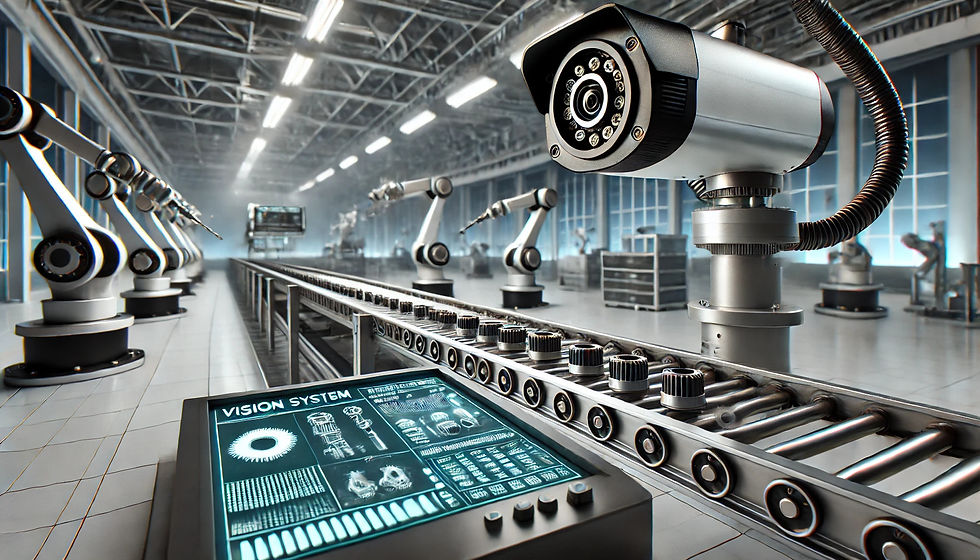

Industrial automation has transformed manufacturing processes, enabling greater efficiency, precision, and scalability across diverse industries. At the heart of this revolution lies vision cameras, sophisticated imaging devices that play a pivotal role in capturing and analyzing visual data to drive automation. This article explores the multifaceted role of vision cameras in industrial automation, highlighting their capabilities, applications, and contributions to enhancing productivity and quality in manufacturing operations.

Capturing the Invisible:

The Power of Vision Cameras

Vision cameras serve as the eyes of industrial automation systems, capturing visual information from the production environment with remarkable clarity and precision. Equipped with high-resolution sensors and advanced optics, these cameras can detect subtle details, patterns, and anomalies that may go unnoticed by the human eye. From inspecting product quality to guiding robotic movements, vision cameras provide invaluable insights that enable automation systems to make informed decisions in real time.

Quality Control and Inspection:

Ensuring Precision and Consistency

One of the primary applications of vision cameras in industrial automation is quality control and inspection. By capturing images of manufactured components or products, vision cameras can analyze them for defects, dimensional accuracy, and surface finish. Whether it's detecting flaws in automotive parts, verifying label placement on packaging, or ensuring uniformity in electronic components, vision cameras enable manufacturers to maintain high standards of quality and consistency throughout the production process.

Guiding Robotic Operations:

Precision in Motion

Vision cameras play a crucial role in guiding robotic operations, enabling robots to perform complex tasks with precision and accuracy. By capturing images of the work environment and processing them in real time, vision-guided robots can identify objects, locate targets, and navigate obstacles with ease. Whether it's picking and placing items on a conveyor belt, assembling intricate components, or sorting products based on specific criteria, vision-guided robots leverage the power of vision cameras to execute tasks with unparalleled efficiency and reliability.

Process Optimization and Efficiency:

Driving Continuous Improvement

Vision cameras contribute to process optimization and efficiency by providing valuable data insights that drive continuous improvement initiatives. By monitoring production processes in real time, vision cameras can identify bottlenecks, inefficiencies, and opportunities for optimization. Whether it's optimizing workflow layouts, adjusting machine settings for optimal performance, or implementing predictive maintenance strategies, vision cameras empower manufacturers to streamline operations, reduce downtime, and maximize productivity.

Advanced Applications:

Pushing the Boundaries of Possibility

Beyond traditional manufacturing applications, vision cameras are increasingly being deployed in advanced applications that push the boundaries of industrial automation. From augmented reality systems that overlay digital information onto physical objects to autonomous vehicles that navigate complex environments, vision cameras enable a wide range of innovative solutions that enhance safety, efficiency, and intelligence in industrial settings.

Conclusion:

In conclusion, vision cameras are indispensable tools in industrial automation, providing the visual intelligence that drives efficiency, precision, and innovation across manufacturing operations. From quality control and inspection to guiding robotic operations, optimizing processes, and enabling advanced applications, vision cameras play a multifaceted role in shaping the future of manufacturing. As technology continues to evolve, the capabilities of vision cameras will only continue to expand, unlocking new possibilities and driving further advancements in industrial automation.

Comments