Seeing Beyond Human Limits: The Power of Vision Inspection Systems in Quality Control

- jeksonvision128

- Aug 18, 2023

- 3 min read

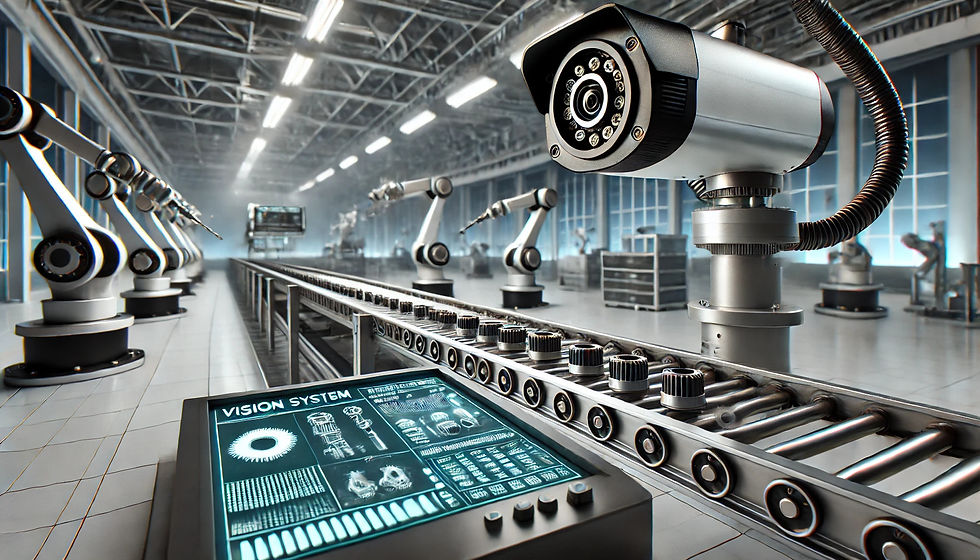

In the intricate world of modern manufacturing, ensuring impeccable quality and precision is not just a goal; it's a fundamental necessity. As production processes become more complex and demands for consistency escalate, industries are embracing innovative technologies to redefine the landscape of quality control. Among these game-changers stands the Vision Inspection System – a remarkable technological advancement that has the potential to revolutionize how we perceive and achieve quality in manufacturing.

Unveiling the Vision Inspection System

Imagine a system with the ability to scrutinize and analyze products with an unmatched level of detail and accuracy. The Vision Inspection System is precisely that – a cutting-edge solution that harnesses the power of advanced imaging, artificial intelligence, and machine learning algorithms to inspect and assess products in real-time.

At its core, the Vision Inspection System represents a leap forward in quality control. It possesses the capacity to identify defects, anomalies, and deviations that might elude the human eye. From manufacturing lines to packaging processes, this technology has the potential to reshape the way industries approach quality assurance.

The Technological Marvel of Precision

The Vision Inspection System offers a multitude of advantages that extend far beyond traditional quality control methods:

1. Pinpoint Accuracy:

The system's ability to capture and analyze intricate product details ensures that even the most minuscule defects are brought to light, maintaining an exceptional level of quality.

2. Real-Time Vigilance:

Unlike manual inspections, which are subject to human limitations, the Vision Inspection System operates in real-time, enabling immediate identification of defects and deviations. This rapid response reduces the likelihood of flawed products reaching consumers.

3. Consistency and Reliability:

Human inspectors might exhibit variations in judgment due to factors like fatigue. The Vision Inspection System, however, adheres consistently to programmed standards, ensuring uniformity across production batches.

4. Elevated Speed and Efficiency:

With its swift processing capabilities, the system can inspect products at high speeds, resulting in improved production efficiency and increased throughput.

5. Data-Driven Insights:

By accumulating and analyzing vast datasets, the Vision Inspection System provides manufacturers with valuable insights that can be leveraged to optimize processes, prevent future defects, and refine product design.

Transforming Industries Across the Spectrum

The versatility of the Vision Inspection System positions it as a pivotal asset across a diverse range of industries:

1. Manufacturing Marvel:

From intricate components to complex assemblies, manufacturers can ensure that each piece meets stringent quality standards before integration into the final product.

2. Pharmaceutical Precision:

In the pharmaceutical sector, the system verifies pill counts, monitors packaging integrity, and detects any irregularities in labeling, contributing to patient safety.

3. Edible Excellence:

For consumables, the Vision Inspection System examines packaging seals, checks for contaminants, and ensures uniformity in appearance and size.

4. Package Perfection:

In the world of packaging, the system confirms label placement, verifies barcode readability, and assesses the overall integrity of the package.

5. Electronics Evolution:

From circuit boards to intricate components, the system can identify soldering defects, pin misalignments, and other imperfections in electronic products.

A Glimpse into the Future

In a world where technology continues to redefine our capabilities, the Vision Inspection System offers a glimpse into the future of quality control and manufacturing excellence. Its remarkable ability to enhance accuracy, speed, and data-driven decision-making is revolutionizing industries and redefining the very notion of quality.

In an era where precision is paramount, the Vision Inspection System stands as a testament to the potential of technology to transform manufacturing processes, ensure unparalleled quality, and uphold the highest standards of excellence. As industries wholeheartedly embrace this technological marvel, they are paving the way for a future where flawlessness and efficiency become synonymous with product creation – setting new benchmarks for success and innovation in a rapidly evolving global marketplace.

Comments