Revolutionizing Pharma Packaging with Smart Camera Technology

- jeksonvision128

- Nov 12, 2024

- 5 min read

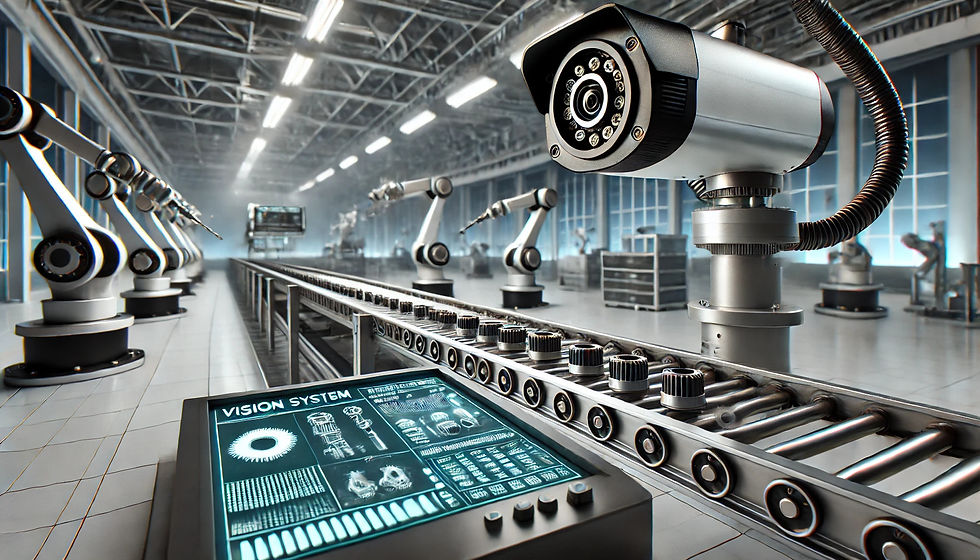

In the ever-evolving pharmaceutical industry, ensuring the integrity, safety, and compliance of packaged products is paramount. As packaging becomes increasingly sophisticated and regulations around labeling and product safety grow more stringent, manufacturers are turning to innovative solutions to streamline their processes. Smart camera technology for pharma packaging is one such breakthrough, playing a crucial role in automating quality control, enhancing traceability, and improving overall efficiency.

Smart cameras, integrated with advanced imaging and AI-driven analytics, offer a cutting-edge approach to monitor and verify packaging processes in real-time. These cameras are equipped with high-resolution imaging, powerful processing capabilities, and AI algorithms that can instantly detect anomalies, label errors, and even assess product integrity. Here's how smart camera technology is transforming pharma packaging.

1. Automating Quality Control

Pharmaceutical packaging demands precision to ensure that every package meets the highest quality standards. Even a small deviation in packaging can lead to significant safety risks or regulatory violations. Traditional manual inspection processes are time-consuming, error-prone, and costly. Smart cameras, however, are capable of performing detailed inspections at high speeds, detecting minute defects such as misprints, damaged packaging, incorrect labels, and missing seals.

With AI algorithms embedded in smart cameras, defects can be identified and flagged in real-time, reducing the chances of faulty products reaching consumers. The cameras’ ability to assess product quality against preset standards ensures that only packages meeting the required specifications are sent for distribution, significantly improving the overall quality control process.

2. Enhancing Traceability and Compliance

As regulations around pharmaceutical packaging continue to tighten globally, traceability has become a critical concern for manufacturers. Smart cameras for pharma packaging play a pivotal role in ensuring compliance with serialization and traceability regulations such as the Drug Supply Chain Security Act (DSCSA) in the United States and the European Falsified Medicines Directive (FMD).

These cameras can capture detailed images of serialized barcodes or QR codes on each package, verifying the correct labeling and ensuring that products are traceable throughout the supply chain. With automated data collection, smart cameras eliminate the risk of human error in tracking and recording serialization information, making it easier for manufacturers to maintain comprehensive records for regulatory reporting and audits.

3. Increasing Production Efficiency

One of the most significant advantages of integrating smart cameras into pharma packaging is the boost to production efficiency. Traditional manual inspection processes can slow down production lines and lead to bottlenecks, especially when high-volume production is required. Smart cameras, on the other hand, provide real-time quality checks at the speed of production, automatically identifying and rejecting defective packages without halting the assembly line.

This results in faster packaging cycles, reduced downtime, and the ability to process larger volumes of products in a shorter time frame. Additionally, since smart cameras can perform multiple inspections simultaneously—such as verifying labels, seals, and packaging integrity—they help ensure that every step of the process is handled efficiently, leading to significant time and cost savings.

4. Real-Time Data and Reporting

Smart cameras integrated with vision systems not only detect errors but also collect valuable data throughout the packaging process. This data is analyzed in real-time and can be used for monitoring production performance, identifying trends, and optimizing packaging workflows. By providing immediate feedback on packaging operations, smart cameras allow manufacturers to take corrective actions quickly, reducing waste and improving efficiency.

Moreover, the data captured by smart cameras can be used to generate detailed reports, providing valuable insights for quality assurance teams and enabling them to track packaging performance over time. This data-driven approach ensures that packaging processes are continually improving and staying compliant with industry standards.

5. Ensuring Product Integrity

Beyond just checking for visual defects, smart cameras can assess product integrity by ensuring that packaging materials such as blister packs, bottles, and vials are sealed correctly and remain secure during transportation. These cameras are capable of detecting issues like missing seals, damaged containers, or poorly sealed caps that could compromise the safety and efficacy of the pharmaceutical product inside.

By preventing the shipment of compromised products, smart cameras help safeguard patients from potential harm and minimize the risk of costly recalls due to product defects. This level of scrutiny ensures that pharmaceutical manufacturers consistently deliver high-quality products to the market.

6. Integrating with Other Technologies for Smarter Packaging

The power of smart cameras for pharma packaging increases when integrated with other advanced technologies such as robotics, artificial intelligence (AI), and machine learning. Smart cameras can work in tandem with robotic systems to reject defective packages and direct the correctly packaged products to the next phase of production or distribution.

AI algorithms can further enhance the accuracy of these systems by learning from past inspection data and continuously improving their defect detection capabilities. Over time, this integration enables pharma manufacturers to build smarter packaging lines that are highly efficient, responsive, and adaptive to changing production demands.

7. Reducing Human Error and Labor Costs

Manual inspection, although effective, is susceptible to human error, especially during long production runs. Fatigue, distractions, and inconsistencies in inspection criteria can lead to errors, resulting in product defects or regulatory non-compliance. Smart cameras eliminate the need for manual inspection by providing consistent, objective, and highly accurate quality control.

By automating the inspection process, smart cameras reduce the reliance on manual labor, lowering labor costs while improving the consistency and accuracy of inspections. This also allows human operators to focus on higher-level tasks, such as overseeing production processes and ensuring that equipment is functioning optimally.

8. Meeting Global Packaging Regulations

Different regions around the world have unique pharmaceutical packaging regulations. In addition to serialization and traceability requirements, these regulations often mandate specific labeling, tamper-evidence features, and safety seals. Smart cameras are programmed to recognize and verify these regulatory markings, ensuring that packaging is compliant with local, national, and international laws.

For instance, in regions like Europe, manufacturers must comply with the Falsified Medicines Directive (FMD), which mandates that pharmaceutical packaging include a unique identifier for each package. Smart cameras can scan these identifiers and ensure that every package meets these stringent requirements, helping manufacturers stay compliant across different markets.

Conclusion

Smart camera technology for pharma packaging is revolutionizing the way pharmaceutical companies approach packaging, quality control, and compliance. By automating the inspection process, enhancing traceability, and ensuring product integrity, smart cameras streamline production, improve efficiency, and reduce the risk of errors. With the growing complexity of global regulations and the demand for higher quality standards, smart cameras are a crucial tool in enabling pharmaceutical manufacturers to meet these challenges while improving overall operational performance.

As the industry continues to embrace digital transformation, smart camera systems will play an increasingly important role in ensuring that pharma packaging meets the highest standards of safety, compliance, and efficiency.

Comments