Precision Assurance: The Role of Tablet Inspection Systems in Pharmaceutical Quality Control

- jeksonvision128

- Nov 9, 2023

- 2 min read

In the realm of pharmaceuticals, where precision and quality are non-negotiable, tablet inspection systems emerge as indispensable tools in maintaining the highest standards of product integrity. These advanced systems play a pivotal role in pharmaceutical quality control, ensuring that every tablet produced meets stringent quality criteria. In this article, we delve into the crucial role of tablet inspection system and how they contribute to precision assurance in the pharmaceutical industry.

I. The Significance of Quality Control in Pharmaceuticals:

A. Patient Safety:

Pharmaceuticals directly impact patient health, making quality control paramount.

Ensuring the safety and efficacy of medications is a fundamental responsibility of pharmaceutical manufacturers.

B. Regulatory Compliance:

Strict regulatory standards govern the pharmaceutical industry.

Compliance with these standards is mandatory to obtain approvals and maintain a reputable standing in the market.

C. Brand Reputation:

A pharmaceutical company's reputation hinges on the quality of its products.

Consistent high-quality products foster trust among healthcare professionals and consumers.

II. Understanding Tablet Inspection Systems:

A. Definition and Purpose:

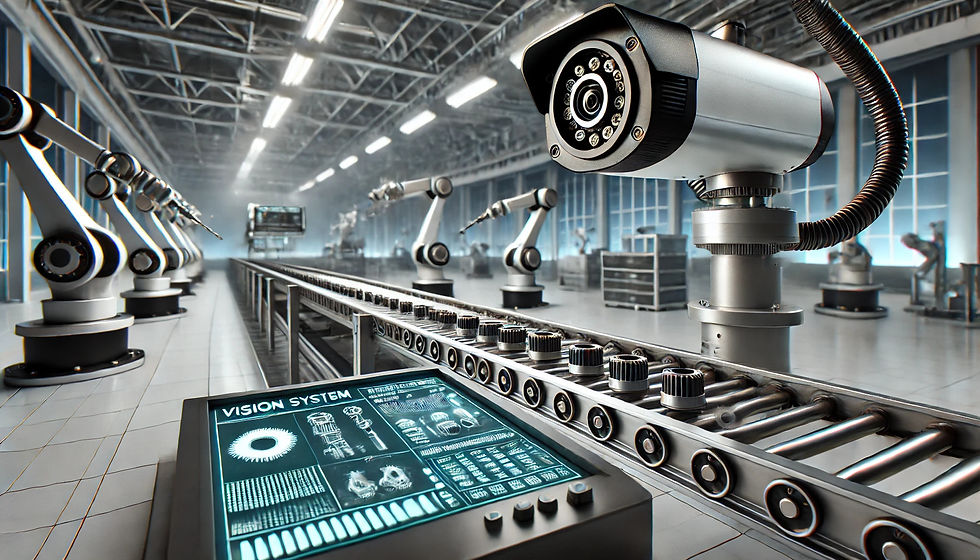

Tablet inspection systems are sophisticated machinery designed to examine each tablet for defects and deviations.

The primary purpose is to identify and rectify any issues that may compromise the tablet's quality.

B. Components of Tablet Inspection Systems:

Visual Inspection: High-resolution cameras and image processing algorithms identify visual defects such as cracks, chips, or discoloration.

Weight Variation: Ensures uniformity in tablet weight, preventing dosage discrepancies.

Size and Shape Analysis: Measures and verifies the dimensions of each tablet to maintain consistency.

Color Inspection: Detects variations in color that may signal manufacturing irregularities.

III. Precision Assurance in Action:

A. Visual Inspection:

Automated cameras capture detailed images of each tablet at high speeds.

Image processing algorithms analyze these images for visual defects with exceptional accuracy.

B. Weight Variation Control:

Precise weight control mechanisms ensure that each tablet meets specified weight criteria.

Prevents variations that could impact the efficacy of the medication.

C. Size and Shape Analysis:

Laser-based systems measure the dimensions of each tablet, ensuring uniformity.

Guarantees consistency in dosage and ease of administration.

D. Color Inspection:

Spectrophotometers or colorimeters assess the color of tablets, identifying discrepancies.

Ensures uniform appearance and adherence to brand standards.

IV. Advancements in Tablet Inspection Technology:

A. Artificial Intelligence (AI):

Integration of AI enhances the ability of tablet inspection systems to adapt and learn from new data.

Improves accuracy and reduces false positives/negatives.

B. High-Speed Inspection:

Advanced tablet inspection systems operate at high speeds, accommodating the demands of modern pharmaceutical production lines.

Minimizes production bottlenecks and enhances efficiency.

C. Connectivity and Data Analytics:

Tablet inspection systems are often integrated into broader manufacturing systems.

Real-time data analytics provide insights into production trends and potential areas for improvement.

V. Ensuring Compliance and Future Developments:

A. Regulatory Adherence:

Tablet inspection systems play a crucial role in meeting and exceeding regulatory standards.

Compliance is essential for gaining approvals and maintaining a strong market position.

B. Future Trends:

The future of tablet inspection systems lies in continued integration with Industry 4.0 technologies.

Enhanced connectivity, automation, and predictive maintenance will further optimize pharmaceutical manufacturing processes.

VI. Conclusion:

Precision assurance in pharmaceuticals is synonymous with the meticulous inspection of each tablet produced. Tablet inspection systems stand as guardians of quality, leveraging advanced technologies to ensure that every tablet meets the highest standards of safety and efficacy. As pharmaceutical manufacturing continues to evolve, these systems will play an increasingly vital role in maintaining precision and excellence in the production of life-saving medications. Through their unwavering commitment to quality control, tablet inspection systems contribute significantly to the well-being of patients and the continued trust of healthcare professionals and consumers alike.

Comments