Enhancing Quality Control: The Role of Vision Systems in Manufacturing

- jeksonvision128

- Jul 19, 2024

- 5 min read

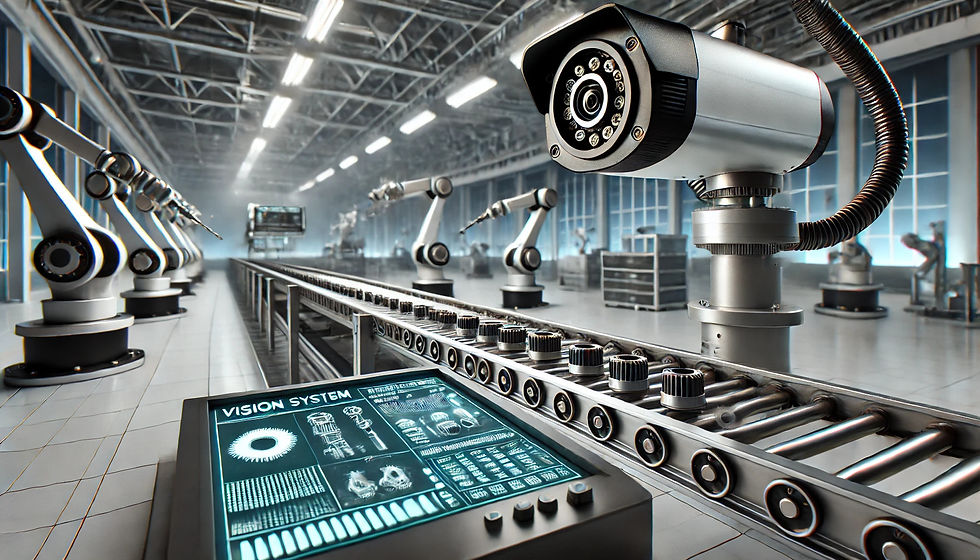

In the fast-paced world of manufacturing, maintaining high standards of quality control is crucial. As production lines become more automated and demand for flawless products increases, vision systems have emerged as essential tools in enhancing quality control. These systems, leveraging advanced imaging and processing technologies, provide manufacturers with the ability to inspect, measure, and analyze products with unparalleled precision and efficiency. Let's delve into how vision systems for manufacturing are revolutionizing quality control in manufacturing.

What Are Vision Systems?

Vision systems, also known as machine vision systems, consist of cameras, lighting, sensors, and computer software designed to capture and analyze visual information. These systems are capable of identifying defects, measuring components, and verifying assembly processes in real-time. Unlike human inspectors, vision systems can operate continuously without fatigue, ensuring consistent and objective quality control.

Key Components of Vision Systems

1. Cameras and Sensors

High-resolution cameras capture detailed images of products as they move along the production line. These cameras are capable of capturing minute details, allowing for the detection of even the smallest defects. Sensors help in positioning and triggering the cameras at the right moments, ensuring that images are captured accurately and at the right time.

2. Lighting

Proper illumination is crucial for capturing clear and accurate images. Vision systems use various lighting techniques, such as backlighting, coaxial lighting, and structured lighting, to enhance image quality. The choice of lighting depends on the specific application and the type of defects that need to be detected. For example, backlighting can highlight silhouettes, making it easier to detect dimensional defects, while coaxial lighting can eliminate surface reflections.

3. Image Processing Software

Advanced software algorithms process the captured images, detecting defects, measuring dimensions, and verifying the presence or absence of components. The software can also compare images against predefined standards and tolerances. These algorithms use techniques such as pattern recognition, edge detection, and blob analysis to identify and analyze features in the images. Machine learning and artificial intelligence are increasingly being integrated into image processing software, enhancing the system's ability to learn from data and improve its accuracy over time.

4. Data Analysis and Storage

The data collected by vision systems can be stored and analyzed for further insights. This data can help identify trends, track production performance, and support continuous improvement initiatives. For example, analyzing defect patterns can help identify root causes and implement corrective actions. Data storage is also important for traceability and compliance with regulatory requirements.

How Vision Systems Enhance Quality Control

1. Defect Detection

One of the primary applications of vision systems is defect detection. Whether it's a cosmetic flaw, a dimensional error, or a functional defect, vision systems can identify issues that might be missed by human inspectors. For example, in the electronics industry, vision systems can detect soldering defects, missing components, and misalignments with high accuracy. In the automotive industry, vision systems can inspect parts for surface defects, cracks, and other imperfections, ensuring that only high-quality components are used in the assembly process.

2. Measurement and Verification

Precision is paramount in manufacturing, and vision systems excel at measuring and verifying product dimensions. By comparing the actual measurements to the specified tolerances, vision systems ensure that every product meets the required standards. This capability is particularly valuable in industries like automotive and aerospace, where even minor deviations can have significant consequences. Vision systems can measure dimensions such as length, width, height, and diameter, as well as more complex features such as angles and radii.

3. Assembly Verification

Vision systems play a critical role in verifying assembly processes. They can check for the correct placement of parts, the presence of screws or fasteners, and the proper alignment of components. In the pharmaceutical industry

, vision systems ensure that labels are correctly applied and that packaging is intact, thereby preventing errors that could compromise patient safety. They can also verify that safety seals and tamper-evident features are properly in place, ensuring the integrity of pharmaceutical products.

4. Process Control and Optimization

By providing real-time feedback on the production process, vision systems enable manufacturers to identify and address issues promptly. This real-time monitoring helps in maintaining consistent quality and minimizing waste. Vision systems can detect trends and patterns in defects, allowing manufacturers to make adjustments to the production process to prevent future occurrences. This capability supports lean manufacturing principles by reducing rework and scrap, thereby improving overall efficiency and productivity.

5. Traceability and Documentation

Vision systems enhance traceability by capturing images and data at various stages of the production process. This information can be linked to individual products, creating a detailed record of their journey through the manufacturing process. This traceability is essential for industries subject to strict regulatory requirements, such as medical devices and food and beverage. For instance, in the food industry, vision systems can track the origin of ingredients, monitor production conditions, and verify labeling accuracy, ensuring compliance with food safety regulations.

6. Compliance with Industry Standards

Industries such as automotive, aerospace, medical devices, and pharmaceuticals are subject to stringent quality and safety standards. Vision systems help manufacturers comply with these standards by ensuring that products meet all required specifications. They provide documented evidence of quality control measures, which can be crucial during audits and inspections. By maintaining high levels of accuracy and consistency, vision systems support manufacturers in achieving certifications and maintaining compliance with industry regulations.

The Future of Vision Systems in Manufacturing

As technology advances, vision systems will continue to evolve and become even more integral to manufacturing processes. The integration of IoT (Internet of Things) devices, blockchain technology, and artificial intelligence will enhance the accuracy, security, and efficiency of these systems. IoT devices can provide real-time monitoring of environmental conditions, while blockchain technology ensures tamper-proof records, and AI can predict and mitigate risks before they impact the supply chain.

Emerging technologies such as deep learning and augmented reality (AR) are also poised to revolutionize vision systems. Deep learning algorithms can improve the system's ability to recognize complex patterns and defects, while AR can provide operators with real-time visual feedback and guidance during inspection and assembly processes.

Conclusion

Vision systems have become indispensable in modern manufacturing, offering a powerful solution for enhancing quality control. By integrating vision systems into their production lines, manufacturers can achieve higher levels of precision, consistency, and efficiency. These systems not only improve defect detection and measurement accuracy but also support assembly verification, process optimization, and traceability. As technology continues to advance, the capabilities of vision systems will only grow, further solidifying their role in the pursuit of manufacturing excellence.

In a world where consumer expectations are rising and regulatory requirements are becoming more stringent, vision systems offer a competitive edge by ensuring that products meet the highest standards of quality and safety. By leveraging the power of vision systems, manufacturers can build trust with their customers, reduce operational costs, and maintain a strong reputation in the marketplace. As the manufacturing landscape continues to evolve, vision systems will remain at the forefront, driving innovation and excellence in quality control.

4o

Comments