Enhancing Pharmaceutical Quality Control: Tablet Inspection Systems

- jeksonvision128

- May 14, 2024

- 2 min read

In the pharmaceutical industry, ensuring the safety and efficacy of medications is paramount. Quality control measures play a crucial role in upholding these standards, particularly in the manufacturing of tablets and other solid dosage forms. Tablet inspection systems have emerged as indispensable tools in pharmaceutical quality assurance, offering advanced capabilities for detecting defects, ensuring consistency, and maintaining compliance with regulatory requirements. In this article, we delve into the significance of tablet inspection systems in enhancing pharmaceutical quality control.

Automated Precision:

Tablet Inspection Systems Revolutionize Manufacturing

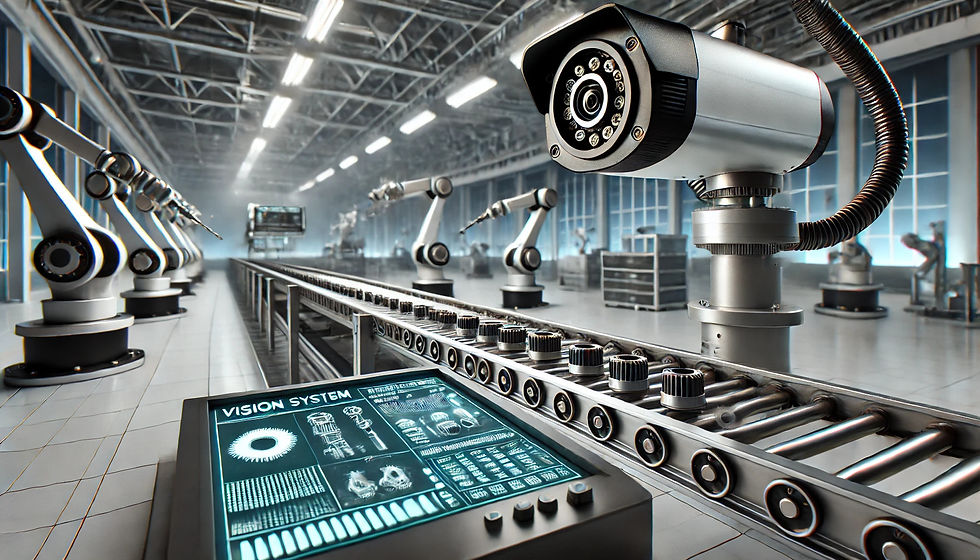

Tablet inspection systems represent a paradigm shift in pharmaceutical manufacturing, offering automated precision that surpasses traditional manual inspection methods. These systems utilize cutting-edge technologies such as machine vision, artificial intelligence, and high-resolution imaging to inspect tablets with unparalleled accuracy and efficiency. By automating the inspection process, tablet inspection systems minimize human error, increase throughput, and reduce production costs. Moreover, their ability to detect subtle defects that may go unnoticed by manual inspection ensures the consistent quality of pharmaceutical products, safeguarding patient safety and satisfaction.

Ensuring Compliance and Safety:

Tablet Inspection Systems in Pharma

In an industry governed by stringent regulatory standards, compliance with quality control requirements is non-negotiable. Tablet inspection systems play a pivotal role in ensuring compliance with regulatory guidelines such as Good Manufacturing Practices (GMP) and Pharmacopeial standards. These systems provide objective and reproducible inspection results, documenting deviations and facilitating traceability throughout the manufacturing process. By identifying and rejecting defective tablets, they mitigate the risk of substandard or counterfeit products entering the market, thereby safeguarding public health and maintaining the integrity of the pharmaceutical supply chain.

High-Speed Tablet Inspection Systems:

Optimizing Production Efficiency

In today's fast-paced manufacturing environment, efficiency is key to remaining competitive. High-speed tablet inspection systems leverage advanced image processing algorithms and high-performance cameras to inspect tablets at remarkable speeds without compromising accuracy. By rapidly analyzing thousands of tablets per minute, these systems enable manufacturers to achieve higher throughput levels while maintaining stringent quality standards. This enhanced efficiency translates into improved productivity, reduced time-to-market, and greater profitability for pharmaceutical companies, driving innovation and growth in the industry.

Innovations in Tablet Inspection Technology:

Advancing Quality Assurance in Pharmaceuticals

The evolution of tablet inspection technology continues to push the boundaries of quality assurance in pharmaceuticals. Recent innovations include multispectral imaging for enhanced detection of surface defects, real-time data analytics for predictive maintenance and process optimization, and integration with track-and-trace systems for end-to-end supply chain visibility. Furthermore, the integration of artificial intelligence and machine learning algorithms enables tablet inspection systems to adapt and learn from inspection data, continuously improving their performance and reliability over time. These advancements underscore the ongoing commitment of the pharmaceutical industry to embrace cutting-edge technologies in pursuit of excellence in quality assurance.

Conclusion:

In conclusion, tablet inspection systems represent a cornerstone of pharmaceutical quality control, providing manufacturers with the tools they need to uphold the highest standards of product quality, safety, and compliance. By harnessing the power of automation, precision imaging, and advanced analytics, these systems not only detect defects but also drive process optimization, innovation, and continuous improvement in pharmaceutical manufacturing. As technology continues to evolve, tablet inspection systems will play an increasingly pivotal role in shaping the future of pharmaceutical quality assurance, ensuring that patients worldwide have access to safe, effective, and reliable medications.

Comments