Elevating Quality Assurance: Inspection Systems for Tablets and Capsules

- jeksonvision128

- Sep 25, 2023

- 2 min read

In the pharmaceutical and nutraceutical industries, ensuring the highest level of product quality is not only a regulatory requirement but also a fundamental responsibility to safeguard consumer health and trust. Tablets and capsules are among the most commonly used dosage forms, making their quality control critical. The implementation of advanced inspection systems has become a cornerstone of quality assurance in tablet and capsule production. In this article, we will explore the importance of inspection systems for tablets and capsules and how they are elevating the standards of quality assurance.

The Significance of Quality Assurance in Tablet and Capsule Production

Tablets and capsules are widely consumed forms of medication and dietary supplements. Ensuring their quality is paramount for several reasons:

Patient Safety: Tablets and capsules are ingested, and their quality directly impacts patient safety. Inaccurate dosages or contaminated products can have serious health consequences.

Regulatory Compliance:

The pharmaceutical and nutraceutical industries are subject to strict regulations. Compliance with Good Manufacturing Practices (GMP) and other standards is mandatory to ensure product safety and efficacy.

Consumer Trust:

Product quality directly affects consumer trust. Consistently high-quality products enhance brand reputation and customer loyalty.

Challenges in Quality Control

Traditional quality control methods, such as manual inspection, have limitations, including:

Subjectivity:

Manual inspections are prone to human error and subjectivity, leading to inconsistent results.

Speed and Volume:

The pharmaceutical industry often requires high-speed production to meet demand, making manual inspection impractical for large batches.

Inefficiency:

Manual inspection is time-consuming and can lead to production bottlenecks.

How Inspection Systems Address These Challenges

Inspection systems designed for tablets and capsules offer a comprehensive solution to these challenges. Key features and benefits include:

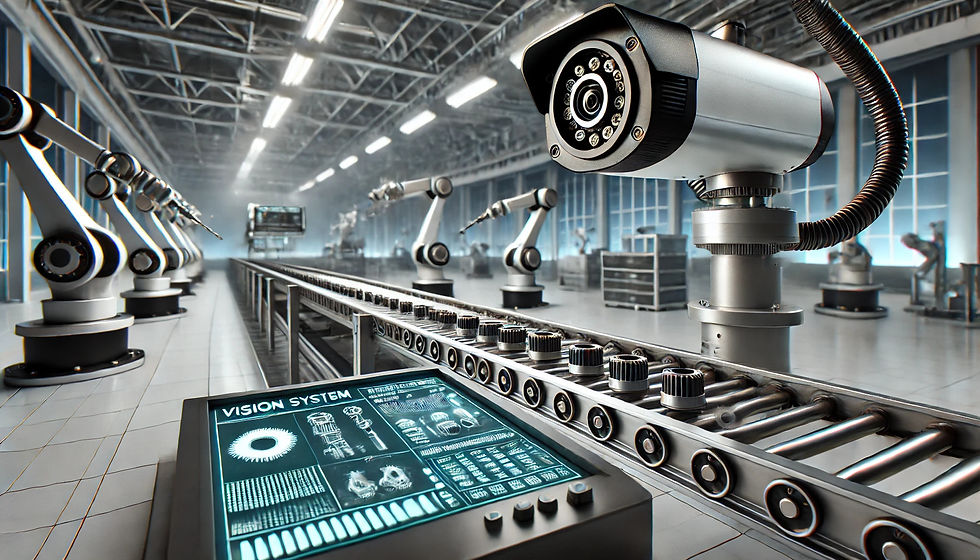

Automation:

Inspection systems automate the process, ensuring consistent and high-speed inspections. This eliminates human error and enhances efficiency.

High Precision Imaging:

Advanced cameras and imaging technology capture high-resolution images of each tablet or capsule, enabling precise defect detection and measurement.

Defect Recognition:

Utilizing artificial intelligence and machine learning algorithms, these systems can identify defects, such as chipping, cracks, size variations, or contamination, that may be difficult to detect with the human eye.

Data Logging:

Detailed data records are created for each product, providing a digital trail for quality assurance and compliance purposes.

Real-time Monitoring:

Inspection systems can perform real-time monitoring, automatically rejecting defective products and ensuring only high-quality items move forward in the production process.

Benefits of Inspection Systems

The benefits of implementing inspection systems for tablets and capsules are substantial:

Enhanced Quality:

Inspection systems provide consistent and precise quality control, reducing the risk of defective products reaching consumers.

Speed and Efficiency:

These systems operate at high speeds, improving production efficiency and reducing costs.

Compliance:

Automated inspection ensures compliance with regulatory standards and GMP requirements.

Data-Driven Decision Making:

The data generated by inspection systems can be used for process optimization and continuous improvement.

Consumer Trust:

Reliable quality assurance builds consumer trust and confidence in the brand.

Conclusion

In an era where pharmaceutical and nutraceutical companies face stringent regulatory requirements and heightened consumer expectations, inspection systems for tablets and capsules have emerged as indispensable tools for quality assurance. These systems combine automation, precision imaging, defect recognition, and real-time monitoring to ensure that every tablet and capsule leaving the production line meets the strictest quality standards. By elevating the standards of quality assurance, these systems not only enhance patient safety but also contribute to brand reputation and long-term success in the highly competitive healthcare and dietary supplement industries.

Comments