Boosting Manufacturing Efficiency with OEE IoT Integration

- jeksonvision128

- Oct 4, 2024

- 3 min read

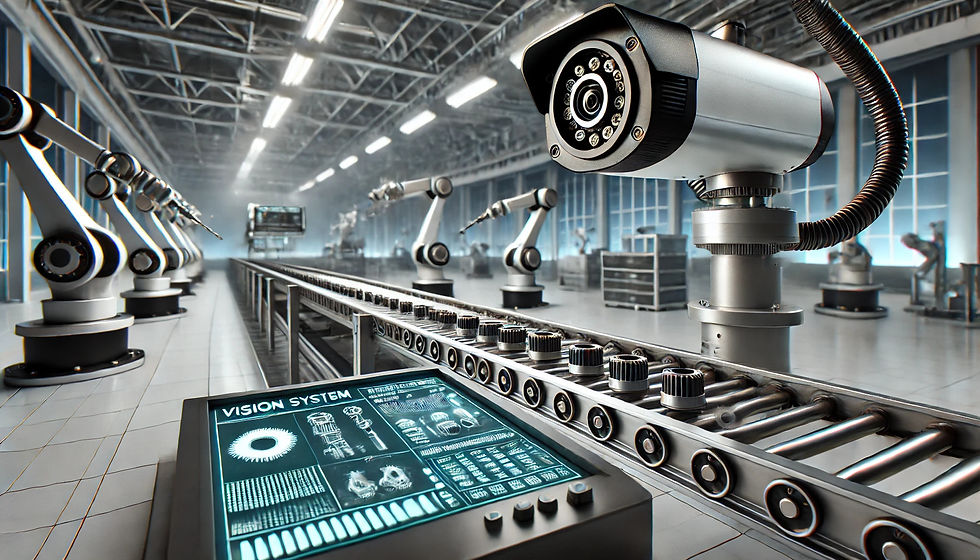

In the evolving landscape of manufacturing, maximizing efficiency is key to staying competitive and profitable. One of the most effective strategies for improving operational performance is through the integration of Overall Equipment Effectiveness (OEE) with the Internet of Things (IoT), commonly known as OEE IoT. By harnessing the power of IoT technologies, manufacturers can collect real-time data, gain actionable insights, and make informed decisions to enhance productivity and reduce costs.

What is OEE IoT?

OEE is a widely used metric that measures the efficiency of manufacturing equipment based on three factors: availability, performance, and quality. It provides a clear indication of how well a production line is running and highlights areas for improvement. Traditionally, gathering data for OEE calculations was manual and time-consuming. However, with the advent of IoT, manufacturers can now automate data collection and streamline the entire process, creating what is known as OEE IoT.

OEE IoT involves using IoT-enabled sensors and devices to monitor machines, capture data, and provide insights in real-time. This allows plant managers and operators to have a constant view of machine performance, ensuring they can quickly address inefficiencies, unplanned downtime, or defects. As a result, manufacturing efficiency is optimized without the need for manual intervention.

How OEE IoT Improves Manufacturing Efficiency

Real-Time Monitoring and Data Collection: With IoT-enabled sensors installed on manufacturing equipment, OEE IoT systems can continuously monitor machine performance. These sensors capture critical data such as uptime, speed, and defect rates, enabling real-time visibility into the production process. This automated data collection eliminates the need for manual monitoring, freeing up valuable time and reducing the risk of human error.

Predictive Maintenance: One of the standout benefits of OEE IoT is its ability to facilitate predictive maintenance. By analyzing the data collected from equipment, IoT systems can predict when a machine is likely to fail or require maintenance. This allows manufacturers to schedule repairs before a breakdown occurs, reducing costly downtime and improving overall equipment availability.

Optimized Production Performance: OEE IoT systems provide detailed insights into how equipment is performing relative to its capacity. By identifying bottlenecks, underperforming machines, or areas of wasted resources, manufacturers can optimize production settings to ensure equipment operates at peak efficiency. This leads to improved performance, faster cycle times, and increased output.

Enhanced Quality Control: OEE IoT also plays a crucial role in improving product quality. By tracking quality metrics in real-time, manufacturers can detect defects early in the production process. This allows for immediate corrective action, minimizing the production of defective goods and reducing rework costs. As a result, product quality is enhanced, and customer satisfaction improves.

Data-Driven Decision Making: With the data generated by OEE IoT systems, manufacturers gain valuable insights into their operations. This data can be used for strategic decision-making, such as optimizing production schedules, adjusting maintenance plans, or even investing in new equipment. The ability to make informed, data-driven decisions leads to increased efficiency and long-term improvements in productivity.

Benefits of OEE IoT Integration

Increased Equipment Availability: OEE IoT helps manufacturers reduce unplanned downtime by enabling proactive maintenance and real-time issue resolution, keeping machines running smoothly.

Higher Production Output: By improving performance and reducing inefficiencies, OEE IoT enables higher production output with minimal disruptions.

Improved Product Quality: Real-time quality monitoring ensures that defects are detected early, leading to consistent production quality and reduced waste.

Cost Reduction: With optimized maintenance schedules, less downtime, and improved production processes, OEE IoT leads to significant cost savings for manufacturers.

Real-World Applications of OEE IoT

Automotive Manufacturing: OEE IoT is widely used in automotive plants to monitor equipment across production lines, ensuring minimal downtime and consistent quality.

Pharmaceutical Industry: In highly regulated industries like pharmaceuticals, OEE IoT helps maintain stringent quality standards by providing real-time insights into the manufacturing process.

Food and Beverage Sector: OEE IoT allows food and beverage manufacturers to optimize production lines, reducing spoilage and improving throughput.

Conclusion

OEE IoT represents a transformative shift in how manufacturers measure and improve equipment effectiveness. By integrating IoT technology with OEE systems, manufacturers can optimize equipment performance, reduce downtime, and improve product quality, leading to greater efficiency and profitability. As more manufacturers adopt OEE IoT, it is set to become a critical tool for driving operational excellence in the industry.

Comments