Beyond the Blister Pack: The Role of Blister Inspection Systems in Quality Control

- jeksonvision128

- Sep 25, 2023

- 3 min read

Blister packs have long been a popular choice for packaging pharmaceuticals, nutraceuticals, and a range of other consumer products. The sleek and convenient design of blister packs provides a protective barrier for individual doses. However, the quality and integrity of these packs are of paramount importance, not only for product efficacy but also for patient safety. Blister inspection systems have emerged as critical tools in maintaining quality control and ensuring that blister packs meet the highest standards. In this article, we explore the pivotal role of blister inspection systems in quality control and their contribution to product safety and consumer confidence.

The Significance of Quality Control in Blister Pack Production

Blister packs serve as a primary packaging solution for a variety of products, including pharmaceuticals, nutraceuticals, and medical devices. Maintaining quality control in blister pack production is essential for the following reasons:

Product Protection: Blister packs protect individual doses from environmental factors such as moisture, light, and contamination, ensuring product stability and effectiveness.

Patient Safety: In pharmaceuticals, the quality of blister packs directly impacts patient safety, as any defects or breaches could compromise the integrity of the product.

Regulatory Compliance: Compliance with stringent regulatory standards, including Good Manufacturing Practices (GMP), is imperative to ensure product safety, efficacy, and regulatory approval.

Challenges in Blister Pack Quality Control

Quality control in blister pack production presents several complex challenges:

Volume and Speed: The pharmaceutical industry often operates high-speed production lines to meet market demand, making manual inspection impractical.

Complex Packaging: Blister packs come in various shapes and sizes, and defects can manifest in different ways, requiring a versatile inspection approach.

Human Error: Manual inspection processes are subject to human error and subjectivity, leading to inconsistencies in quality control.

How Blister Inspection Systems Address These Challenges

Blister inspection systems offer a comprehensive solution to the challenges faced in blister pack quality control. Key features and benefits of these systems include:

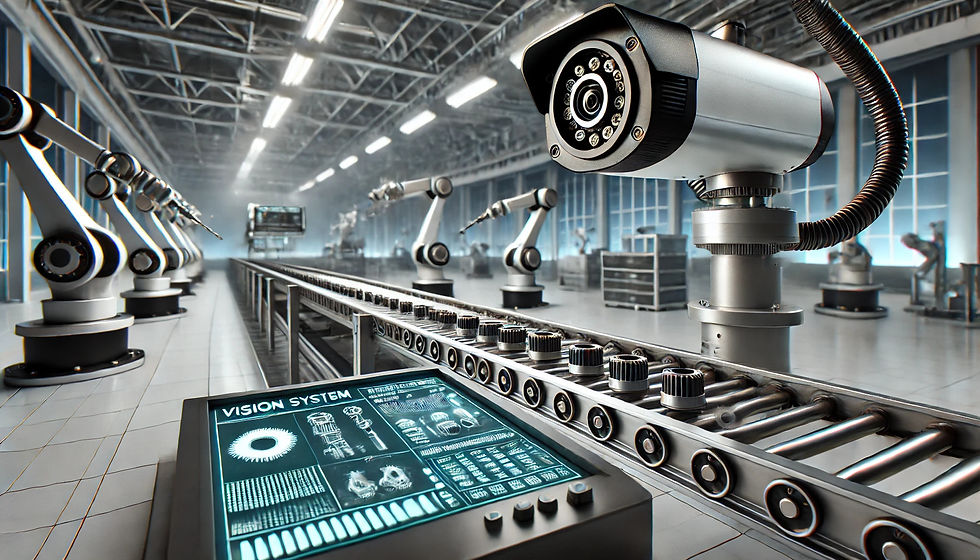

Automation: Inspection systems automate the quality control process, ensuring that inspections are consistent, high-speed, and free from human error. This significantly enhances efficiency.

High-Resolution Imaging: Advanced cameras and imaging technology capture detailed, high-resolution images of blister packs, enabling precise defect detection and measurement.

Defect Recognition: Employing artificial intelligence (AI) and machine learning (ML) algorithms, these systems can identify a wide range of defects, such as breaches, tears, misalignment, or contamination, with remarkable accuracy.

Data Logging: Comprehensive data records are generated for each blister pack, providing a digital trail for quality assurance, regulatory compliance, and traceability.

Real-time Monitoring: Inspection systems perform real-time monitoring and automatically reject defective blister packs, ensuring that only high-quality packs advance in the production process.

Benefits of Blister Inspection Systems Beyond Quality Control

The adoption of blister inspection systems offers benefits beyond quality control:

Enhanced Product Safety: Inspection systems ensure that blister packs are free from defects, protecting product integrity and patient safety.

Speed and Efficiency: Operating at high speeds, these systems improve production efficiency, reduce costs, and enhance throughput.

Regulatory Compliance: Automated inspection ensures compliance with regulatory standards, GMP requirements, and product specifications.

Data Utilization: The data generated by inspection systems can be leveraged for process optimization, continuous improvement, and proactive quality control.

Consumer Trust: Reliable quality assurance builds consumer trust and confidence in the brand, leading to enhanced brand reputation and loyalty.

Conclusion

In blister pack production, blister inspection systems have become indispensable for maintaining quality control and ensuring product safety. These systems, equipped with automation, high-resolution imaging, defect recognition, and real-time monitoring capabilities, go beyond defect detection to contribute to regulatory compliance, process optimization, and consumer trust. By upholding the quality and integrity of blister packs, these systems play a pivotal role in delivering safe and effective products to patients and consumers worldwide, fostering confidence in the pharmaceutical and nutraceutical industries.

Comments